Comprehensive temperature mapping for storage areas, refrigerators, freezers, incubators, and manufacturing spaces. Full qualification documentation for regulatory compliance.

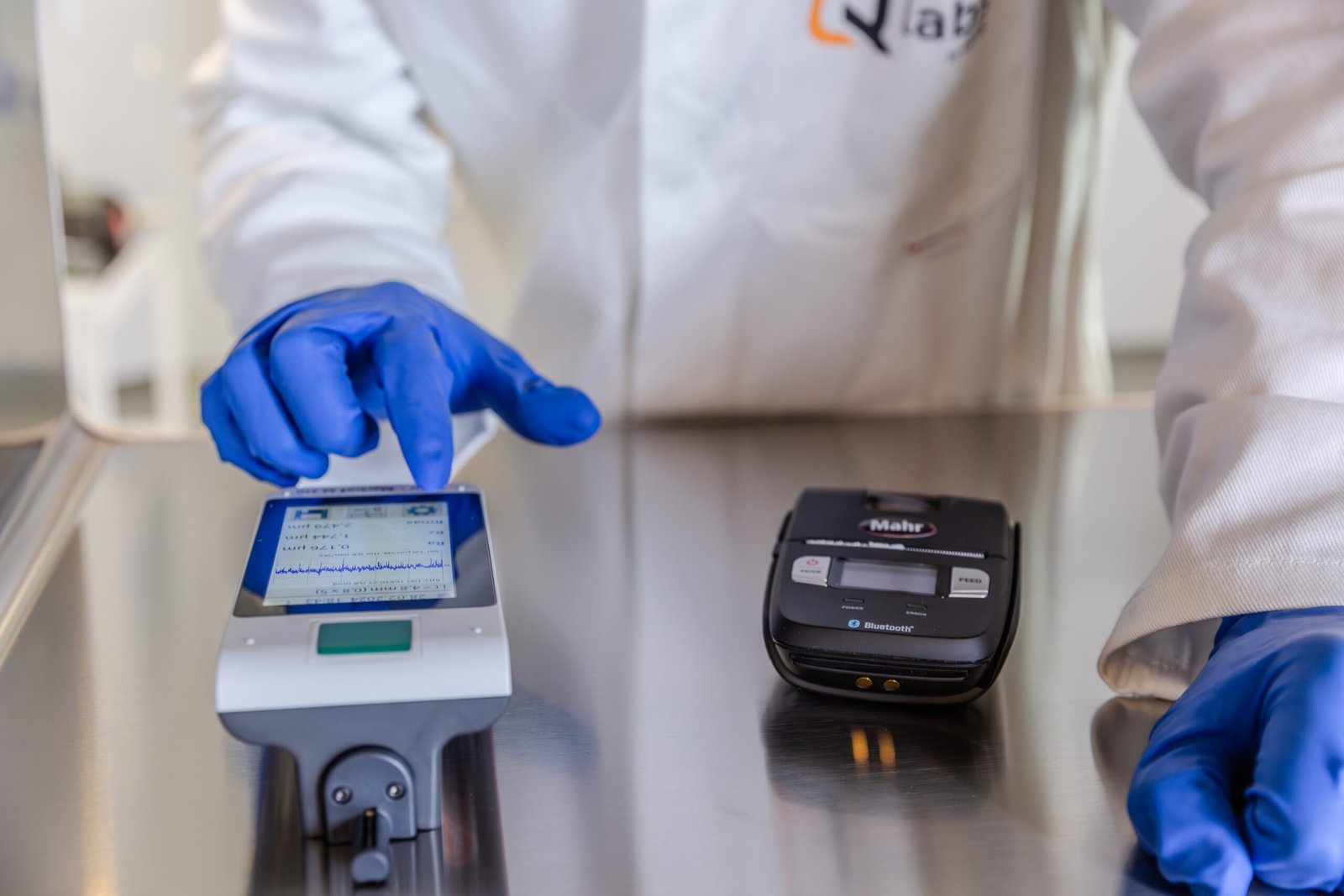

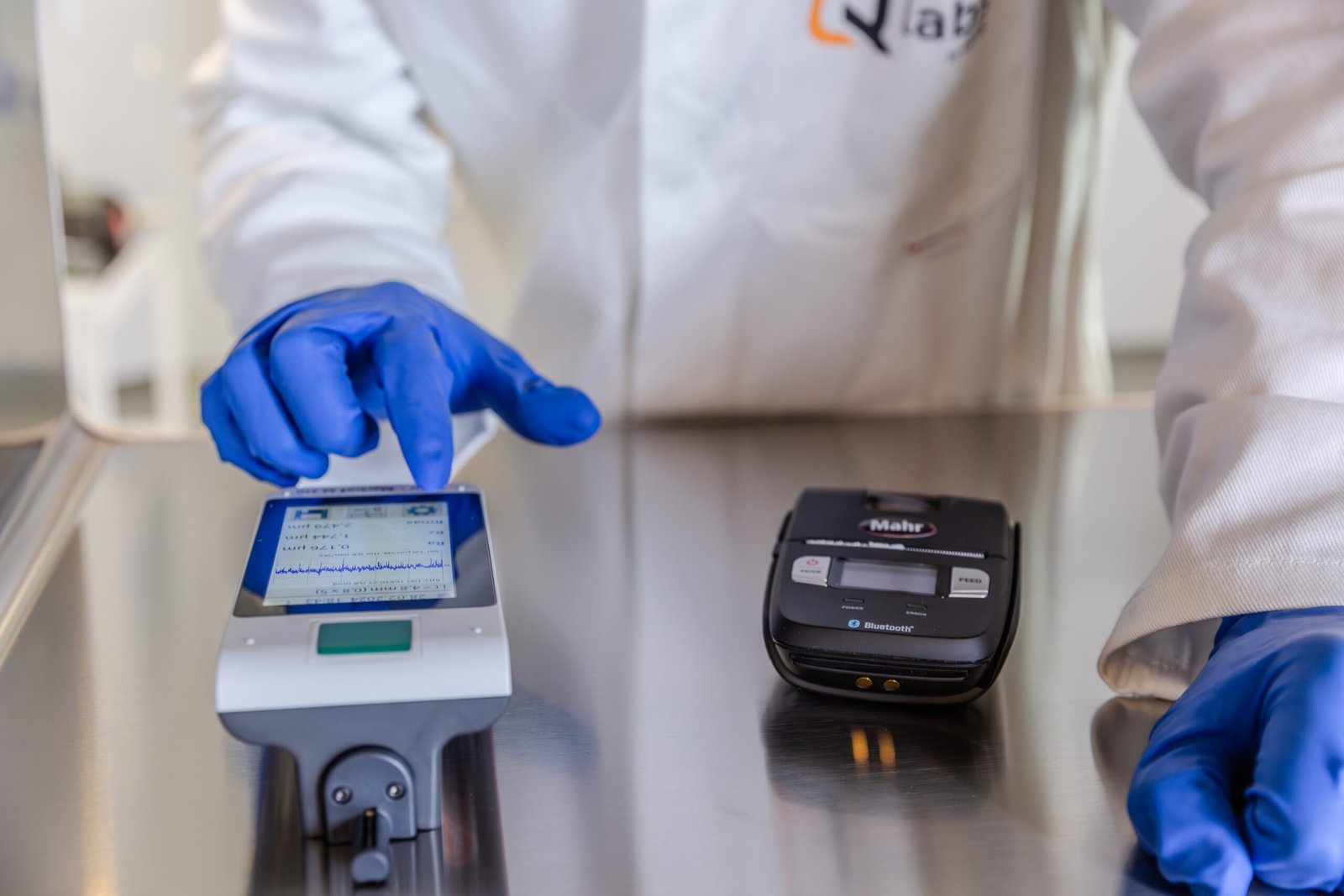

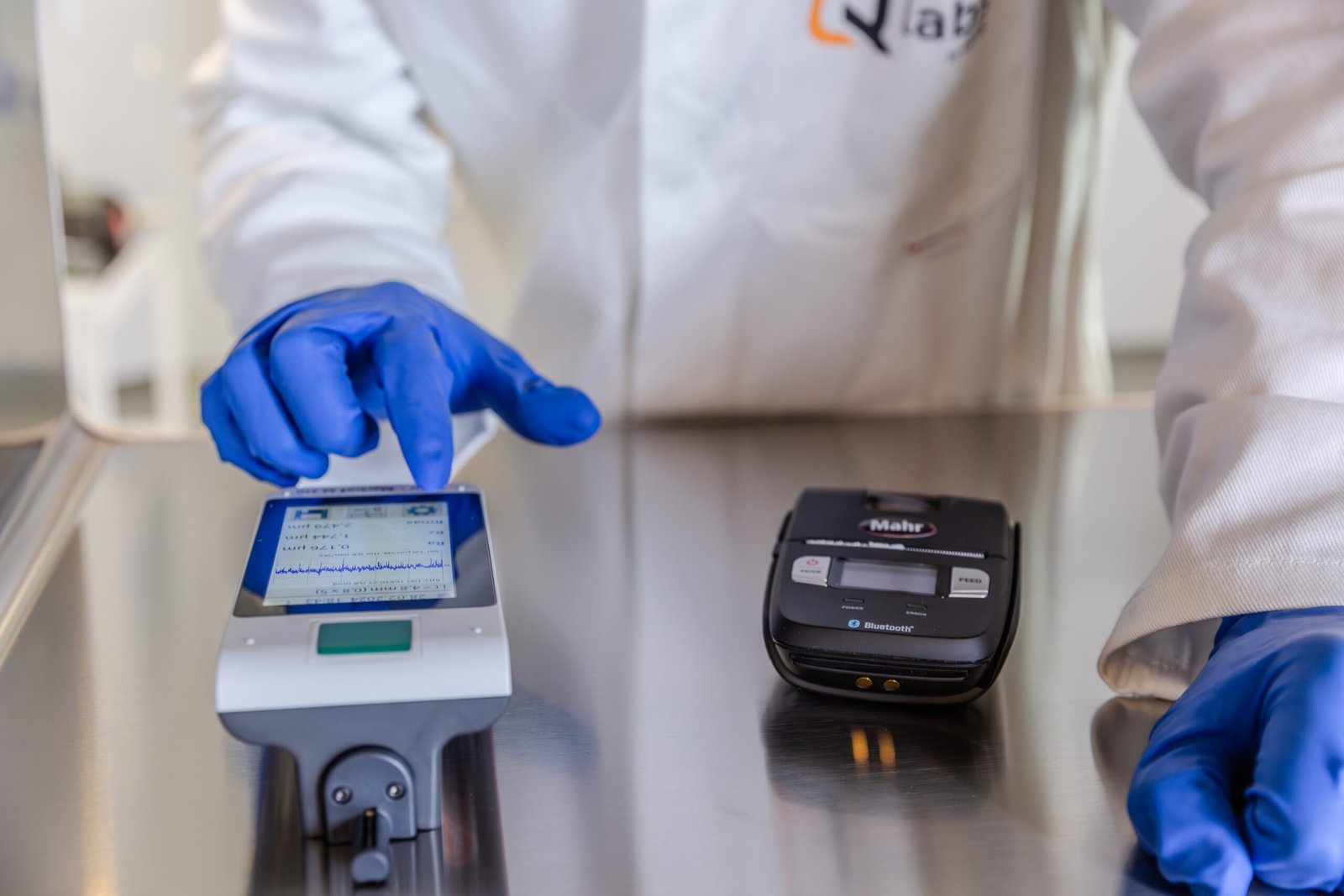

Request temperature mappingWe deliver high-precision measurement services tailored to pharmaceutical, biotechnology, and food technology industries. Our expertise in illuminance, noise level, roughness, non-destructive testing, and temperature mapping ensures accurate, reliable, and compliant quality assurance.

QMeasure specializes in delivering comprehensive measurement services that support your quality assurance processes in regulated environments. From environmental monitoring to material testing, we ensure your measurements meet the highest standards.

Our team uses calibrated equipment and follows strict protocols to provide traceable, audit-ready documentation for all measurement activities, helping you maintain compliance and operational excellence.

Send us a brief request about your measurement needs. We respond with an initial assessment and next steps within 1–2 business days.

QMeasure offers a complete range of measurement services designed to support your quality assurance processes in pharmaceutical, biotech, and food technology facilities.

Comprehensive temperature mapping for storage areas, refrigerators, freezers, incubators, and manufacturing spaces. Full qualification documentation for regulatory compliance.

Request temperature mapping

Precise measurement of lighting conditions and noise levels to ensure compliance with workplace safety standards and optimal working conditions in cleanrooms and production areas.

Get environmental assessment

Surface roughness measurement and non-destructive testing (NDT) to verify material quality, detect defects, and ensure compliance with specifications without damaging the product.

Schedule material testingIn pharmaceutical and biotechnology manufacturing, precise measurements are not just about quality — they're about patient safety, regulatory compliance, and operational reliability.

QMeasure ensures that every measurement is performed with calibrated equipment, documented according to GxP requirements, and delivered with full traceability. Our services support:

All measurements are conducted by trained specialists using calibrated instruments with traceable certification, ensuring your data stands up to the most rigorous audits.

All measurement instruments are regularly calibrated with traceable certification to international standards.

Complete documentation packages that meet FDA, EMA, and other regulatory requirements.

QPS Engineering AG maintains ISO 9001 certification for consistent, quality-focused processes.

Specialists with deep knowledge of pharmaceutical and biotech measurement requirements.

Share details about your facility, equipment, or measurement needs. Our QMeasure experts will contact you with a structured proposal and timeline.