This project focused on the qualification of a large-scale freeze dryer (lyophilizer) designed to process high batch volumes of parenteral drug products. The goal was to ensure GMP-compliant installation, operation, and performance of the equipment under real production conditions, with a…

Qualification Fill and Finish

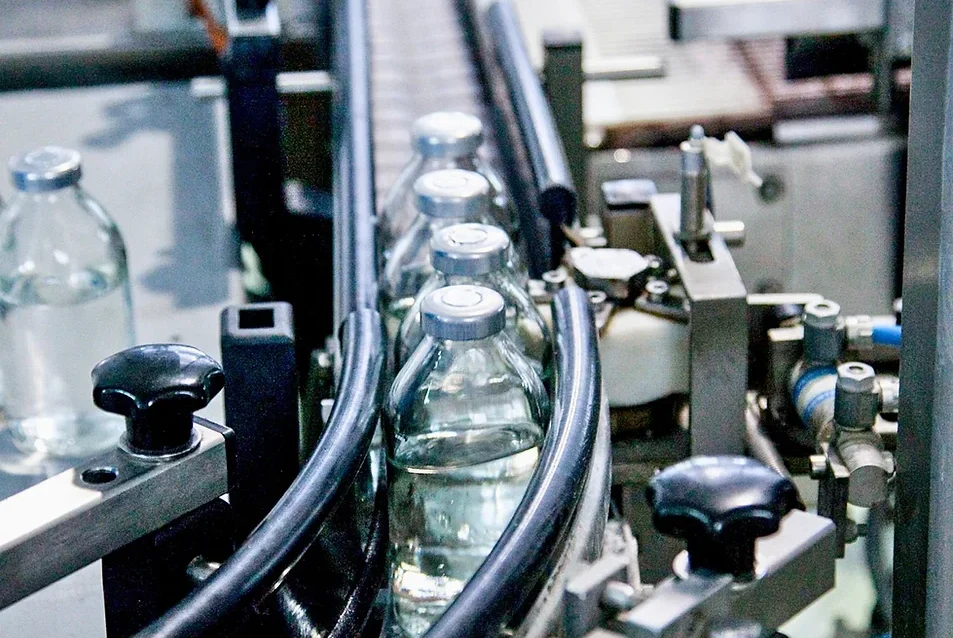

This project involved the full GMP qualification of a complete fill and finish process line, including upstream preparation, aseptic filling, and final container closure. The objective was to commission and qualify the system for clinical and commercial production of sterile drug…

Qualification of AVI Syringes and Vials

This project involved the GMP-compliant qualification of an Automated Visual Inspection (AVI) system for prefilled syringes and vials. The objective was to enhance the detection accuracy for particulate and cosmetic defects while ensuring full compliance with regulatory requirements. QPS Engineering was…

Product Transfer of different Filling Line

This project involved the successful GMP-compliant transfer of pharmaceutical products between two distinct aseptic filling lines. The objective was to ensure process consistency, product integrity, and regulatory compliance while adapting to different technical setups and machine configurations. QPS Engineering led the…