What Are the Benefits of Annex 1 for the Pharmaceutical Industry?

- Enhanced patient safety with stringent contamination controls

- Harmonization of regulations across EU member states

- Encouragement of technological innovation in manufacturing

- Risk-based quality management for tailored approaches

- Expanded guidance covering a wider range of sterile products

Table of Contents

- Understanding the Core Benefits

- 1. Enhanced Patient Safety and Product Quality

- 2. Harmonization and Clarity

- 3. Drives Technological Innovation

- 4. Risk-Based Approach and Flexibility

- 5. Expanded and Updated Guidance

- 6. Improved Cleanroom and Environmental Controls

- Summary: A Game-Changer for the Pharmaceutical Industry

- Conclusion

Understanding the Core Benefits

Annex 1 represents a significant evolution in regulatory guidelines aimed specifically at sterile drug production, biologics, advanced therapies, and primary packaging systems. But what tangible benefits does this new framework promise? Let’s dive into the details.

1. Enhanced Patient Safety and Product Quality

One of the cornerstone benefits of Annex 1 is its rigorous approach to patient safety. The updated guidelines mandate stricter controls designed to minimize the risk of contamination—from microbial and particulate contaminants to endotoxin and pyrogen presence. These enhanced practices ensure that pharmaceutical manufacturers maintain not just compliance but commitment to product integrity and patient safety.

Unlike previous regulations that focused heavily on final product testing, this revision mandates monitoring throughout the entire manufacturing process. This fundamental shift increases the likelihood of detecting contamination at earlier stages—before it can jeopardize product quality or harm patients (Source).

2. Harmonization and Clarity

Navigating regulatory landscapes can be a labyrinthine challenge for pharmaceutical companies, especially those operating internationally. The latest changes in Annex 1 are a proactive step toward harmonizing regulations, particularly across EU member states. This consistency in sterile drug manufacturing practices lays the groundwork for better cross-border cooperation and compliance, crucial for global players in the industry (Source).

Moreover, aligning with global best practices, including FDA guidelines from the U.S., diminishes barriers for international companies, fostering an environment of collaboration and compliance that benefits everyone in the industry.

3. Drives Technological Innovation

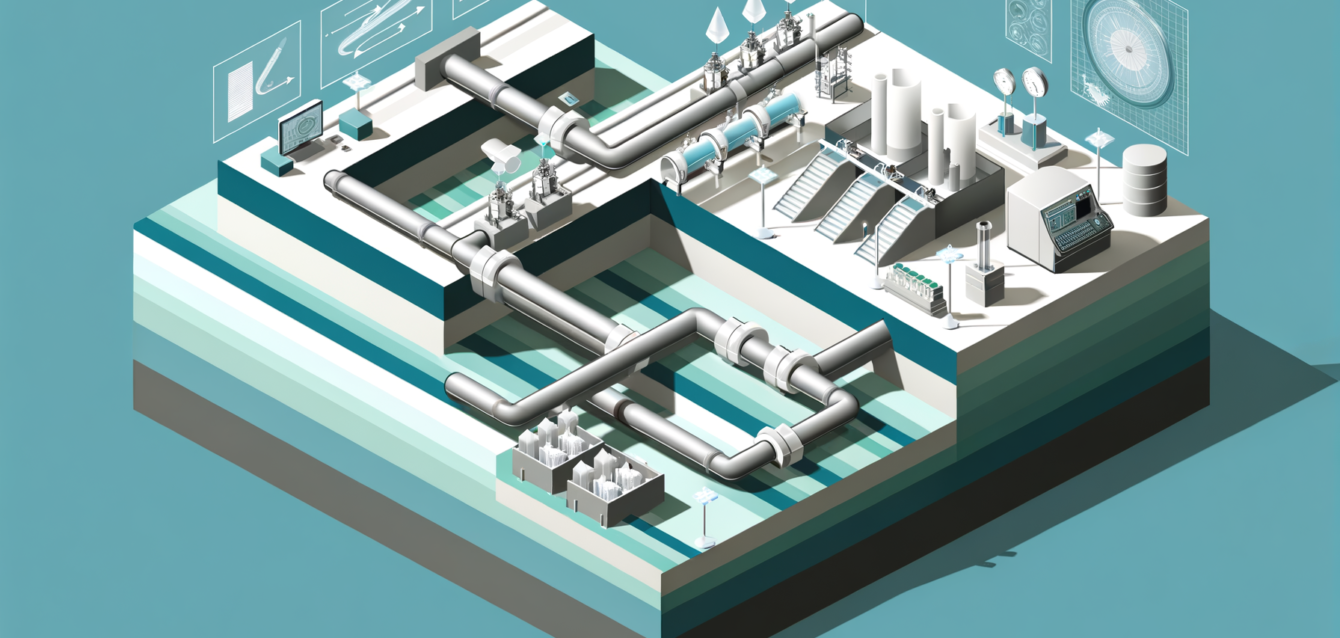

Say goodbye to traditional manufacturing methods! Annex 1 not only encourages but often mandates the adoption of advanced technologies like automation, robotics, and closed processing systems. These innovations dramatically reduce the need for operator interventions—one of the primary risk factors for contamination (Source).

Particularly, the focus on automated fill-finish processes and barrier technologies is likely to transform manufacturing efficiency, safety, and quality. By embracing these technologies, pharmaceutical companies can drastically improve their operational landscapes, setting a new benchmark in sterile drug production (Source).

4. Risk-Based Approach and Flexibility

Traditional quality management will soon be a thing of the past. One of the most significant advancements with the new Annex 1 is its introduction of a risk-based quality management framework. This flexible approach allows manufacturers to tailor their controls and validation strategies according to the specific products and technologies they utilize (Source).

As a result, companies can foster innovation while maintaining a strong focus on risk management. This blend of flexibility and accountability is set to usher in a new era of pharmaceutical manufacturing, where efficiency meets safety.

5. Expanded and Updated Guidance

The scope of Annex 1 is not only broader but also more precise. It now encompasses a wider range of sterile products including sterile powders, lyophilized (freeze-dried) products, and non-filtered formulations. This comprehensive approach lays a robust regulatory framework for modern pharmaceutical manufacturing, ensuring that regulations keep pace with technological advancements (Source & Source).

Another noteworthy addition is the requirement for mandatory media fills—also known as Aseptic Process Simulations—for all sterile forms. This strengthens validation and aseptic processing controls, ensuring the highest standards in drug production.

6. Improved Cleanroom and Environmental Controls

Cleanroom environments are crucial for maintaining the integrity of sterile products, and the revised Annex 1 drives this point home with tightened classifications and real-time monitoring requirements. Manufacturers are now required to monitor particulates as small as 0.5 micrometers, substantially lowering the risk of contamination (Source).

This increased focus on environmental monitoring creates a cleaner and safer manufacturing environment, ultimately benefitting everyone involved, from manufacturers to end users.

Summary: A Game-Changer for the Pharmaceutical Industry

| Benefit | Description |

|---|---|

| Enhanced Patient Safety | Stricter contamination control and earlier detection throughout the process |

| Harmonization of Standards | Consistent application across the EU, easier global regulatory navigation |

| Drives Technological Innovation | Pushes for automation, robotics, and closed-system processes |

| Risk-Based Flexibility | Allows tailored approaches based on detailed risk assessments |

| Expanded Product & Process Coverage | Inclusive of more product types and technologies in the regulatory scope |

| Improved Environmental Controls | Tighter cleanroom particulate and process monitoring requirements |

Conclusion

While the updated Annex 1 certainly poses new challenges—such as technical upgrades, increased documentation demands, and more rigorous validation—the substantial benefits it offers are undeniable. By enhancing patient safety, standardizing high-quality manufacturing practices, and encouraging technological innovation, Annex 1 is not just a regulatory change; it’s a transformative step towards the future of the pharmaceutical industry (Source & Source & Source & Source).

With this evolution paving the way for safer, more efficient manufacturing processes, now is the time for pharmaceutical professionals to adapt. It’s not just a matter of compliance—it’s about leading the charge into a new era of quality and innovation. For more insights on how to navigate these changes and enhance your manufacturing practices, explore QPS Engineering’s services or reach out to our team on LinkedIn.