Visual Inspection in Pharma 2025: Innovations Shaping the Future of Quality Control

- Embrace technology: Invest in AI and machine learning capabilities to optimize inspection processes and improve defect detection.

- Consider outsourcing: Leverage CDMOs or CMOs for visual inspection services to ensure compliance and maintain focus on core competencies.

- Engage in industry events: Participate in conferences to stay updated on best practices, regulations, and technological advancements.

Table of Contents

- The Importance of Visual Inspection in Pharmaceuticals

- Market Growth and Economic Outlook

- Key Technological Trends

- Industry Shifts and Business Strategies

- Conclusion: The Road Ahead

The Importance of Visual Inspection in Pharmaceuticals

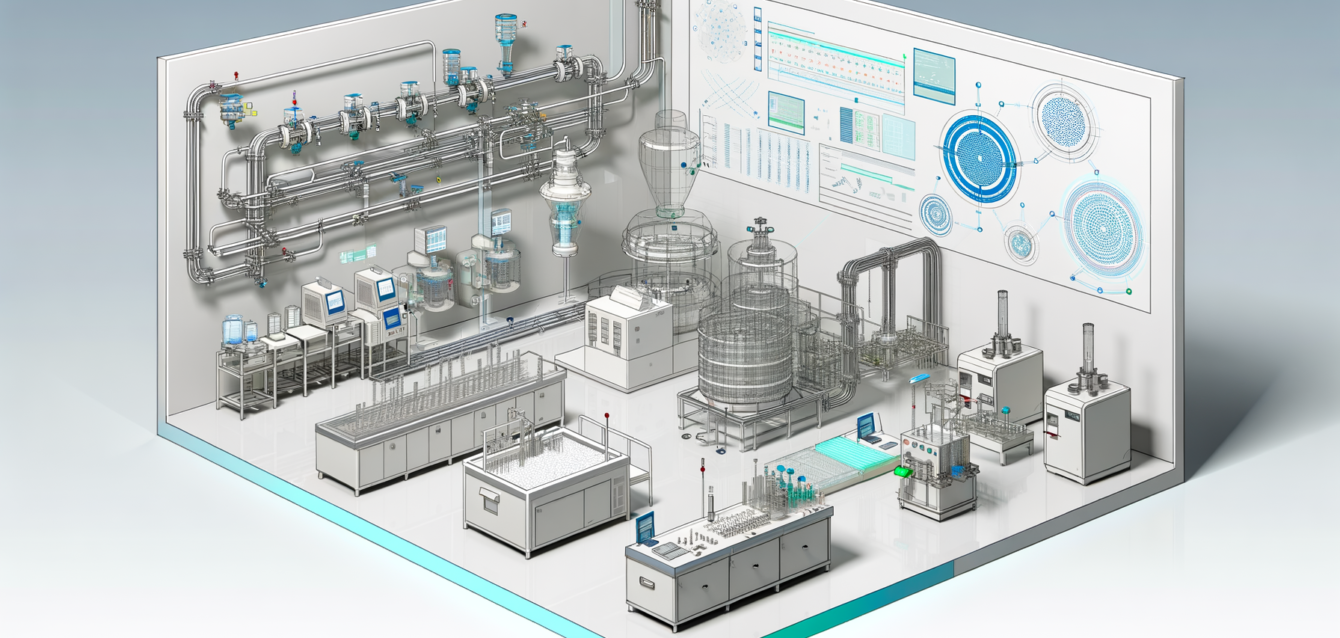

Visual inspection acts as the first line of defense against defects in pharmaceutical products and is paramount for regulatory compliance and quality assurance. The growing complexity of pharmaceutical manufacturing, coupled with stringent regulatory frameworks, has necessitated the evolution of inspection systems. Innovations in visual inspection technologies promise not only to enhance quality control but also to streamline production processes, ultimately ensuring that only the highest standards of safety and efficacy are met.

Market Growth and Economic Outlook

The rapid growth of pharmaceutical visual inspection services is being fueled by increasing technological advancements, leading to a pronounced shift toward automated and semi-automated inspection systems that enhance accuracy, efficiency, and regulatory compliance. As indicated, the visual inspection machines market, specifically for capsules and tablets, is poised for significant growth through 2025 (Market Research Forecast). This burgeoning market underscores the industry’s commitment to integrating advanced technologies into core processes.

The extensive economic implications of these advancements are noteworthy. Pharmaceutical manufacturers are realizing that investing in superior inspection technology not only resolves compliance issues but also translates to a reduction in long-term costs and the mitigation of risks associated with product recalls and non-compliance.

Key Technological Trends

AI and Machine Learning Integration

The introduction of AI-powered machine vision systems in visual inspection is set to transform the landscape by enhancing defect detection capabilities while simultaneously reducing false rejections. This deep learning technology allows for continuous improvement in accuracy as it analyzes historical inspection data, thus optimizing quality assurance processes in pharmaceutical manufacturing (Grand View Research).

Using sophisticated algorithms, manufacturers can develop novel approaches that not only streamline inspections but also uphold higher quality control standards. This is critical as the demand for consistent quality continues to rise amid a backdrop of increasing counterfeit drug concerns.

Advanced Imaging Technologies

The integration of 3D vision systems has paved the way for improved detection of microscopic defects across pharmaceuticals and medical devices. These technologies are especially beneficial as they provide a more comprehensive view, allowing operators to identify issues that would otherwise go unnoticed with traditional imaging systems (Grand View Research).

Additionally, the emergence of cloud-based analytics in the visual inspection process is revolutionizing data management. These tools enable real-time data analysis and accessibility, empowering manufacturers to make informed decisions swiftly.

Human-AI Collaboration

The future of visual inspection is not just about machines taking over; it’s also about enhancing human performance. Emerging systems feature AI-driven facial tracking technology designed to monitor operator attentiveness during manual or semi-automated inspections. Such innovations ensure operators maintain focus and quality in their visual inspections, with interventions like visual alerts or supervisor notifications being triggered when attention lapses are detected (PDA Visual Inspection Forum 2025).

This symbiosis of human intuition and machine efficiency exemplifies the dual approach needed in quality control processes today.

Industry Shifts and Business Strategies

Outsourcing Trends

As pressures mount to meet stringent regulatory requirements and quality assurance standards, many pharmaceutical and medical device companies are increasingly outsourcing visual inspection services to Contract Development and Manufacturing Organizations (CDMOs), Contract Manufacturing Organizations (CMOs), and Contract Research Organizations (CROs) (Grand View Research). This shift not only allows companies to leverage external expertise but also frees them to concentrate on core operations while ensuring compliance.

The surge in outsourced visual inspection processes presents ripe opportunities for market players to broaden their global reach and meet the increasing demand for high-quality pharmaceutical products. Strategic partnerships are becoming a hallmark of the industry, fostering collaboration among manufacturers to better serve the growing global population.

Market Drivers and Challenges

Several compelling market drivers underpin this venture into advanced visual inspection:

- An unwavering commitment to quality control amidst strict regulatory guidelines strengthens the case for automated systems (Market Research Forecast).

- Rising demand for high-throughput manufacturing processes, aiding production efficiency.

- The escalating prevalence of counterfeit drugs necessitating robust inspection systems to safeguard public health.

- The long-term cost-effectiveness of automated inspection compared to traditional manual checks (Market Research Forecast).

On the flip side, organizations face several challenges, including the high initial investment costs that may deter smaller companies from integrating these advanced technologies. Moreover, integrating these sophisticated machines into existing production lines can be complex, and ongoing maintenance adds to the overall ownership costs. Keeping pace with the fast-evolving regulatory landscape and accommodating highly irregular or diverse products also present significant hurdles (Market Research Forecast).

Conclusion: The Road Ahead

As we stride into 2025, the visual inspection landscape in the pharmaceutical industry will undoubtedly continue to evolve at a rapid pace. The integration of advanced technologies promises to enhance accuracy, improve efficiency, and solidify compliance. For professionals navigating these changes, staying informed about the latest trends and innovations can be pivotal to remaining competitive in an increasingly regulated and complex market.

Practical Takeaways:

- Embrace technology: Invest in AI and machine learning capabilities to optimize inspection processes and improve defect detection.

- Consider outsourcing: Leverage CDMOs or CMOs for visual inspection services to ensure compliance and maintain focus on core competencies.

- Engage in industry events: Participate in conferences to stay updated on best practices, regulations, and technological advancements.

As the pharmaceutical sector drives forward, visual inspection will remain integral to ensuring product quality and safety. Companies willing to innovate and adapt to these trends will not only uphold rigorous standards but thrive amidst the challenges of a complex landscape.

For further insights into how QPS Engineering AG can assist with your project management, process engineering, validation, and quality management needs in regulated industries, feel free to contact our team via LinkedIn.